WPC Wall Panels: The New Standard for Global Architectural Finishes

Table of Contents

- A New Era of Wall Decoration and Cladding

- What Makes WPC Wall Panels Different?

- Core Features of the WPC Material System

- Categories of WPC Wall Panel Products

- Popular WPC Panel Types

- Reasons Why WPC Wall Panels Are Dominating Modern Construction

- Aesthetic Benefits That Drive Designer Adoption

- Installation Advantages That Boost Project Efficiency

- Conclusion: A Material Prepared for the Future

1. A New Era of Wall Decoration and Cladding

The building and decoration industry is evolving faster than ever. Architects, developers, and construction firms across the world are seeking materials that perform well, install quickly, reduce long-term maintenance, and also meet sustainability expectations. This changing landscape has opened the door for Wood Plastic Composite (WPC) wall panels, a new-generation material that is redefining both interior and exterior wall finishes.

Originally seen as an alternative to traditional wood, WPC has now become a category of its own—engineered, stable, functional, and sophisticated. From residential renovations to commercial malls and hospitality spaces, WPC Wall Panels have proven their value through superior performance, aesthetic adaptability, and cost efficiency. For global wholesalers, importers, and project developers, it is becoming one of the most strategic product lines in the decorative material market.

2. What Makes WPC Wall Panels Different?

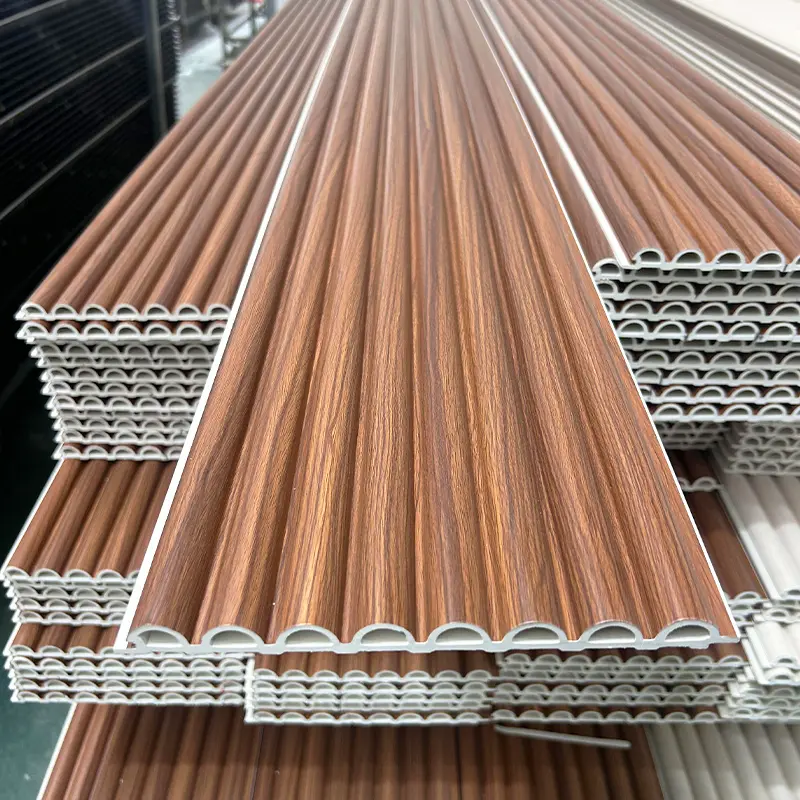

WPC is created through a technologically advanced manufacturing process. Wood fibers or wood powder are blended with polyethylene or PVC resin, along with stabilizers, UV protectors, plasticizers, colorants, and fire-resistant additives. This mixture is heated, extruded, and formed into strong, smooth, and dimensionally stable panels.

3. Core Features of the WPC Material System

- High resistance to humidity and water exposure

- Insect-proof and rot-proof, even in tropical climates

- Stable structure that resists cracks and deformation

- Safe for indoor air quality, as it emits no formaldehyde

- Better durability than plywood or MDF

- Consistent surface finish with long-lasting color

Because WPC is engineered instead of cut from natural timber, it avoids warping, inconsistency in grain, and irregularities—issues that often plague traditional wood materials.

4. Categories of WPC Wall Panel Products

The versatility of WPC is reflected in its range of available designs and structures. Manufacturers now produce numerous panel types aimed at different uses and design needs.

5. Popular WPC Panel Types

- Slatted Decorative Panels with vertical or horizontal flutes

- Acoustic WPC slat systems with felt layers for sound absorption

- Flat or smooth WPC sheets for minimalist interiors

- Exterior façade cladding boards with UV-enhanced layers

- Ceiling panels for both indoor and semi-outdoor spaces

- Customized profiles, including corner trims and structural beams

This product diversity allows businesses to enter multiple market segments without changing their core supply chain or product category.

6. Reasons Why WPC Wall Panels Are Dominating Modern Construction

6.1 Superior Waterproof and Anti-Mold Properties

In many regions—especially Southeast Asia, the Middle East, and coastal markets—humidity and temperature swings create long-term challenges for traditional wall materials. Wood expands and contracts, MDF swells, and painted surfaces peel.

WPC wall panels overcome these issues because their polymer base prevents water penetration. Even in environments with constant moisture exposure, such as:

- Hotel bathrooms

- Fitness club shower areas

- Coastal homes

- High-humidity kitchens

- Commercial spa facilities

- Laundry rooms

WPC maintains its structural integrity and surface finish.

This reliability makes it a preferred material for developers who need predictable performance without frequent maintenance.

6.2 Fire Safety for Commercial and Public Projects

A major advantage of WPC is its fire-retardant potential. Many manufacturers offer WPC panels that reach B1-level fire performance, meaning they:

- Slow flame propagation

- Emit lower smoke

- Provide safer escape time during a fire event

This makes WPC ideal for:

- School buildings

- Libraries

- Hospitals

- Government facilities

- Hotels and resorts

- Multi-story commercial developments

The ability to combine fire safety with attractive design is one of the primary reasons WPC panels are chosen for large-scale modern architecture.

6.3 Durability That Outperforms Traditional Materials

WPC panels withstand elements that weaken most natural materials:

- UV exposure: prevents discoloration and fading

- Termite attacks: insects cannot penetrate composite material

- Impact: resilient structure suitable for high-traffic spaces

- Temperature fluctuations: panels resist contraction and expansion

In exterior applications, advanced co-extrusion technology provides extra layers that protect the core panel from long-term sun exposure and environmental stress.

For commercial and hospitality use, this durability translates into fewer replacements and lower operational costs, especially valuable in long-term leases or large facilities.

6.4 The Advantage of Low Maintenance

The maintenance profile of WPC is extremely appealing for project owners and facility managers. Unlike wood panels that require polishing, or painted walls that crack and peel, WPC panels only need occasional cleaning with water and mild detergent.

This is especially beneficial for:

- Retail stores

- Restaurant chains

- Hotel hallways

- Office buildings

- Public transportation hubs

By reducing maintenance needs, businesses can lower operational expenses by 20–30% over a building’s lifecycle.

7. Aesthetic Benefits That Drive Designer Adoption

7.1 Rich Visual Options and Customization

WPC technology allows precise and consistent surface finishing. Designers can choose from:

- Textured wood grains

- High-end marble patterns

- Concrete and cement finishes

- Premium matte surfaces

- Modern ribbed profiles

- 3D embossed effects

This versatility helps architects create distinctive, contemporary spaces without the cost or maintenance burden of natural materials.

7.2 Fits Global Architectural Styles

Because of its stable structure and clean finishing, WPC blends seamlessly into global design themes such as:

- Scandinavian minimalism

- Modern luxury

- Japanese-inspired simplicity

- Industrial metal-and-wood interiors

- Tropical resort-style décor

Its consistent appearance ensures uniformity across large walls—something difficult to achieve with natural wood.

8. Installation Advantages That Boost Project Efficiency

8.1 Fast and Dust-Free Installation

One of the core strengths of WPC is installation speed. Panels can be installed on metal or wooden battens using screws, clips, or interlocking systems. There is no wet construction, drying time, or painting required.

Compared with brick or tile finishing, WPC systems can shorten installation time by almost half, allowing contractors to:

- Deliver projects under tight deadlines

- Reduce labor hours

- Decrease site waste and debris

- Complete renovations with minimal downtime

For commercial spaces like restaurants or retail stores, this speed directly translates into faster reopening and revenue recovery.

8.2 Suitable for Both Indoor and Outdoor Use

Few decorative materials can transition as smoothly between interior and exterior environments as WPC can.

Indoor Applications

- Feature walls

- Bedrooms

- TV backdrops

- Office partitions

- Hospitality interiors

- Hallways and lobby designs

8.3 Noise Absorption for Sound-Control Projects

WPC acoustic panels have become a favorite among architects designing quiet, comfortable environments. With acoustic felt backing and precise groove spacing, these panels achieve impressive NRC (Noise Reduction Coefficient) results.

They are widely used in:

- Office meeting rooms

- Home theaters

- Hotel reception areas

- Educational spaces

- Recording rooms

The ability to integrate both design and acoustic performance has made WPC a preferred material in modern interior acoustics.

9. Conclusion: A Material Prepared for the Future

WPC wall panels have evolved from a niche alternative to a mainstream architectural solution that meets the standards of durability, performance, and sustainability demanded by modern construction. Their design flexibility, waterproof performance, acoustic benefits, and quick installation make them exceptional for both residential and commercial applications.

For wholesalers, importers, and construction firms, WPC panels offer:

- Stable demand

- Strong profit margins

- Wide application range

- Minimal after-sale issues

As global markets continue migrating toward low-maintenance and environmentally friendly materials, WPC wall panels are positioned to remain one of the most promising categories in the building and interior decoration industries.