UV Marble Sheet : Reshaping Spatial Aesthetics with Technology, Leading a New Trend in Green Homes

UV Marble Sheet : Reshaping Spatial Aesthetics with Technology, Leading a New Trend in Green Homes

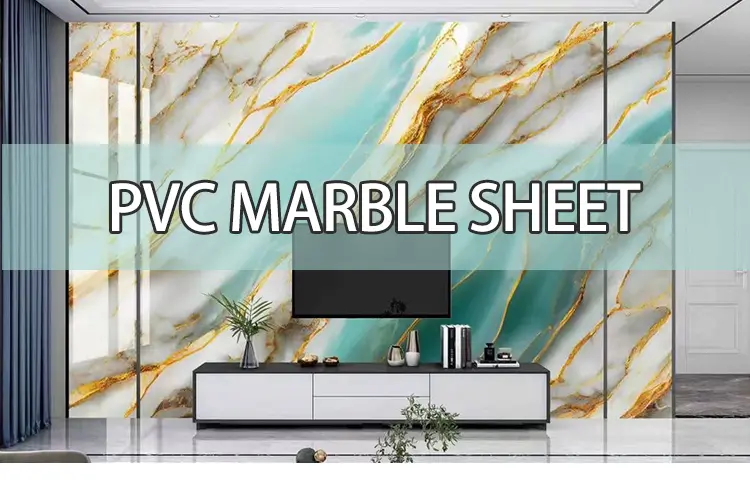

Amidst the rapid development of the contemporary architectural decoration industry, a new decorative material called marble pvc wall cladding panels is quietly changing traditional perceptions of wall and space decoration with its superior performance and exquisite visual effects. As a green building material utilizing cutting-edge UV curing technology, UV panels not only represent a technological leap forward in the decorative panel industry but also become a vital force in driving home and commercial spaces towards environmental friendliness, efficiency, and personalization.

- What is UV Panel? Technology Empowers New Decorative Materials

UV panels, or UV-curable Decorative Panels, are a new type of decorative material made from polymer materials or inorganic sheet materials. After a special surface treatment, they are sprayed with UV paint (ultraviolet curing paint) and then instantaneously cured using advanced UV light equipment.

Compared to traditional panels, their core technological advantage lies in the UV curing process. This process activates the photoinitiators in the coating through ultraviolet radiation of a specific wavelength, triggering an instant polymerization reaction between monomers and oligomers, forming a dense, durable protective film. This process is completed in just seconds, far exceeding the efficiency of traditional paint processes that require extended natural drying or heat baking.

- Superior Properties: Why Are UV Panels Becoming a New Market Favorite?

The multiple performance advantages of UV panels are the fundamental reason they are rapidly gaining favor with designers, contractors, and end users.

1. Environmentally Friendly and Healthy, Ready to Move In

Traditional decoration materials often emit odors (VOCs) over time, while the production process of UV panels achieves virtually zero solvent evaporation. UV paint contains no harmful substances such as heavy metals and benzene, and is odorless after curing, significantly reducing the risk of indoor air pollution. It truly offers "ready to move in" functionality and meets the urgent needs of modern consumers for healthy homes.

2. Superior Physical Properties, Lasting for Life

✅ Ultra-High Hardness and Abrasion Resistance: The film formed after UV curing can achieve a hardness of 4H or higher, far exceeding that of ordinary paint. Its excellent wear and scratch resistance makes it ideal for high-traffic areas such as living rooms, hallways, and commercial spaces, ensuring a pristine finish for long periods.

✅ Chemical Resistance: It is highly resistant to common chemicals such as acids, alkalis, alcohol, and detergents, making cleaning and maintenance exceptionally simple and easy, with a single wipe, saving time and effort.

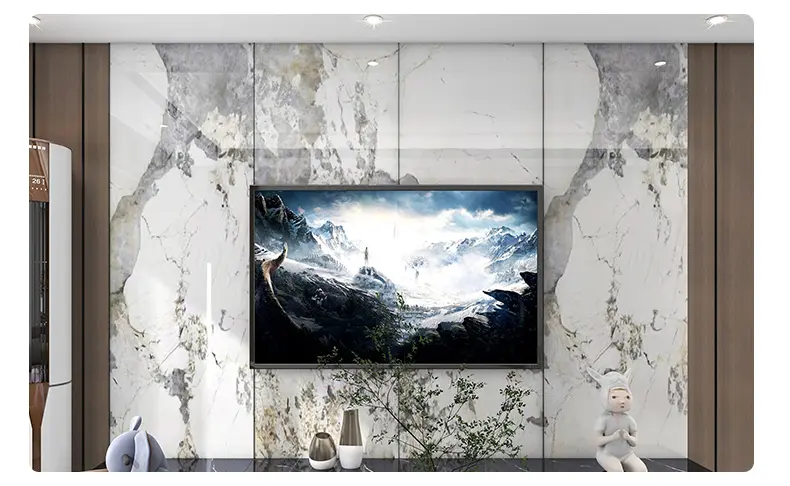

✅ Visual Spectacle: Its surface is smooth and mirror-like, with rich, even hues and a high degree of fidelity to the design. Whether in high-gloss, matte, frosted, or with complex textures like simulated stone or wood grain, it creates a realistic and refined visual effect, significantly enhancing the aesthetic quality of any space.

3.Convenient and Cost-Efficient Installation

Marble type sheets are typically installed using dry hanging, clip-on, or adhesive methods. These methods are fast, require minimal on-site environmental requirements, significantly shorten construction timelines, and reduce labor costs. Their exceptional durability also means a longer lifespan and lower ongoing maintenance costs, making them highly cost-effective in the long term.

- Unlimited Applications: Covering All Scenarios from Home to Business

The application areas of UV panels are constantly expanding, encompassing nearly every interior space.

Residential: TV backdrops, sofa backdrops, and entryways are classic applications for UV panels. Their easy-to-clean properties are particularly advantageous in kitchens and bathrooms, and their wide range of styles perfectly complements a variety of decor styles, from modern minimalist to neo-Chinese.

Commercial Spaces: Office buildings, hotels, restaurants, shopping malls, and brand stores, among other commercial spaces focused on efficiency and image, utilize UV panels extensively for partitions, wall coverings, and furniture. Their wear resistance and fire resistance (requires specific grades) meet public safety requirements, while their stylish appearance effectively enhances a commercial space's brand image.

Specialty Needs: UV panels' antibacterial and disinfectant-resistant properties make them an ideal choice for locations with stringent hygiene and durability requirements, such as hospitals, laboratories, and schools.

- Endless Innovation: Future Development Trends of UV Panels

Technological advancement never ceases, and the UV panel industry continues to innovate.

Diversified Substrates: From initial density fiberboard (MDF) and particleboard to today's gypsum board, calcium silicate board, aluminum alloy, and even glass, UV technology is being integrated with a wider range of substrates, resulting in new products with diverse performance and suitability for different scenarios.

Diversified Effects: High glossy pvc sheets with special effects such as 3D embossing, metallic effects, light transmission, and iridescence are constantly emerging, providing designers with a wider range of creative possibilities.

Multifunctionality: Future UV panels will not only be decorative materials but will likely incorporate a variety of intelligent functions, such as antibacterial, air purification, humidity regulation, and thermal insulation, becoming "breathing" smart wall systems.

Green Intelligent Manufacturing: With the advancement of the "dual carbon" goals, the entire UV panel production industry chain, from raw materials and energy consumption to waste disposal, will place greater emphasis on environmental protection and sustainable development. Digital and intelligent manufacturing will also further enhance product quality and production efficiency.

- Selection and Identification: How to Choose High-Quality UV Panels?

Faced with a dazzling array of products on the market, consumers should pay attention to the following:

Check the base material: A high-quality base material is essential for ensuring the flatness and stability of the board.

Inspect the paint surface: The paint film should be uniform in thickness, smooth and even, free of particles, bubbles, and scratches. High-gloss boards should have a mirror-like effect that is clear and translucent, while matte boards should have a delicate and uniform texture.

Test the hardness: A simple scratch test with a hardness pencil can be performed.

Smell the odor: High-quality pvc wall marble plates should have no irritating odor.

Check the qualifications: Review the product's test report and pay attention to whether its environmental rating (such as E0) and fire rating meet standards. Choose a reputable brand.

- Conclusion

The success of Uv Boards exemplifies the perfect integration of materials science, production technology, and market demand. It demonstrates that technology not only enhances product performance and aesthetics but also leads to a more efficient, healthier, and more sustainable lifestyle. With consumption upgrades and people's ever-increasing pursuit of quality life, UV decorative boards will undoubtedly shine in a wider range of spaces with their irreplaceable advantages, continuing to write a legend of innovation in decorative materials.

- FAQs

1.How can we guarantee quality?

We provide complete pre-sales and after-sales services while ensuring product quality. All products will have been strictly

quality test before packing.

2.Why should you buy from us not from other suppliers?

We have our own factories,and have a wide range of products,we offer customized services to ensure your complete satisfaction.

Fast shipping, never delayed, sample orders are shipped within 3 days, 20GP/40GP orders are shipped within 15--20 days.

3.Can I send a sample? Is it free?

Yes,samples can be provided to you free of charge, you only need to pay the sample delivery charge.

- Free samples

As more and more people choose this product, import and export have also increased their efforts. In order to help people who are cooperating for the first time and trying to sell this product for the first time feel its value, we have launched a free sample activity. If you need it, please feel free to contact us, and we will have a professional service team to connect with you. There is no doubt that UV Marble Sheet will become a hot existence in the decorative materials industry!