UV marble sheet: an innovative choice for modern decorative materials

UV marble sheet: an innovative choice for modern decorative materials

This article comprehensively introduces the characteristics and advantages of UV panels as a new decorative material. Starting with the definition and basic properties of UV panels, the article details their five core advantages: high gloss, strong wear resistance, environmental friendliness and health, rich colors, and easy installation. By comparing them with traditional decorative materials, the article illustrates the significant advantages of UV marble sheets in terms of performance, aesthetics, and longevity. The article also explores the diverse application scenarios of UV panels in home decoration and commercial spaces, and provides practical advice on selecting and installing UV panels. Finally, the article discusses the development prospects of UV panels in the decorative materials market, providing readers with comprehensive reference information.

- Introduction

In contemporary architectural decoration, material selection plays a decisive role in the aesthetics and user experience of a space. With rising environmental awareness and diverse aesthetic preferences, traditional decorative materials are no longer able to fully meet market demand. As a new environmentally friendly decorative material, UV panels, with their unique craftsmanship and superior performance, are becoming a popular choice for Interior Decoration.

- Basic Concepts and Characteristics of Uv Board

UV board is a decorative board whose surface has undergone a UV curing treatment (UV curing). Its core substrate is typically MDF, particleboard, or multi-layer solid wood. It is coated with a special coating and then instantly cured by UV light. This unique process gives UV board its numerous exceptional properties, making it a standout among decorative materials.

From a production perspective, the manufacturing process of marble pvc uv integrates modern technology and precision craftsmanship. First, a high-quality substrate is selected and pre-treated, including sanding and dust removal. UV coating is then evenly applied using advanced equipment, and then immediately fed into the UV curing equipment.

UV board boasts outstanding physical properties, including excellent water and fire resistance, excellent scratch resistance, and flame retardancy and self-extinguishing properties. These properties ensure that UV board maintains its aesthetic appeal over time, reducing maintenance requirements.

- Five Core Advantages of UV Board

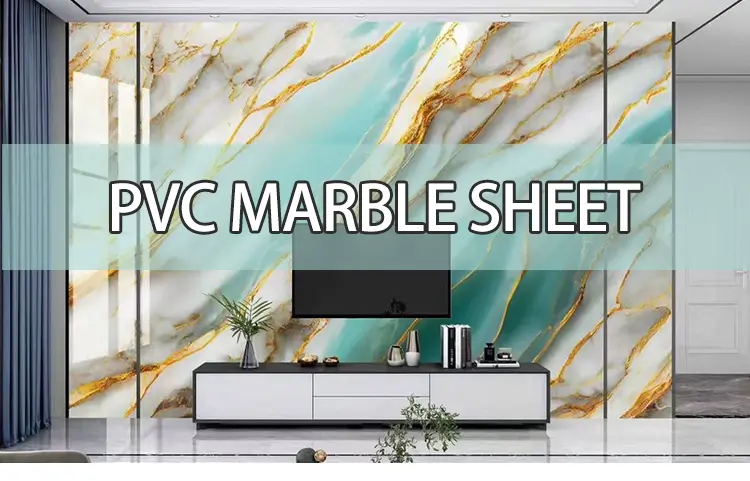

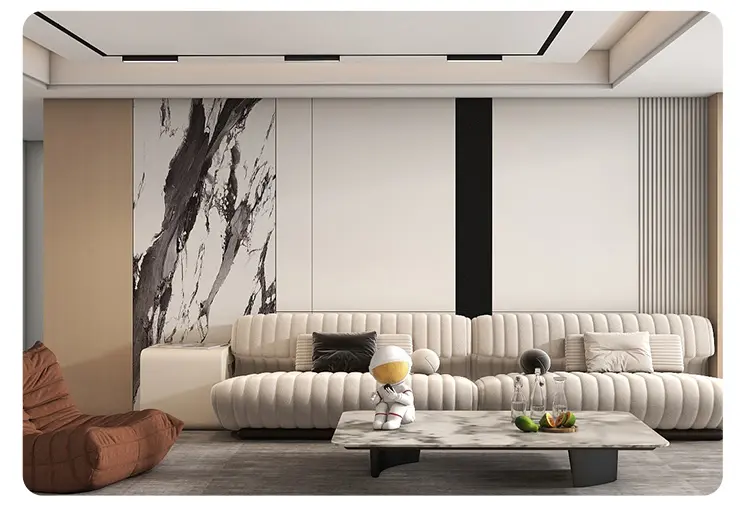

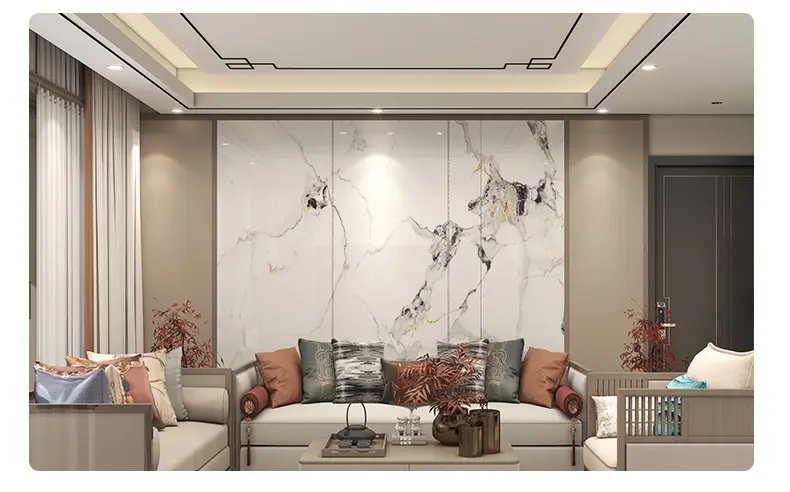

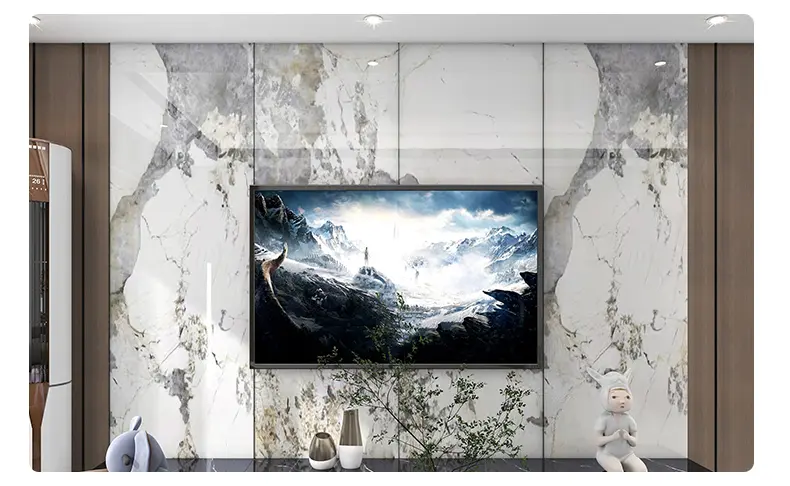

One of the most striking features of UV board is its exceptional high gloss finish. The UV-cured surface exhibits a mirror-like finish, a quality unattainable by many traditional decorative materials. This high-gloss surface is not only aesthetically pleasing but also effectively enhances the sense of light, making indoor environments appear brighter and more spacious. Using UV panels can significantly improve the visual experience, especially in spaces with limited daylight.

UV panels offer exceptional durability. Their high surface hardness and strong impact resistance effectively withstand the scratches and bumps of daily use. Marble senil panels are 3-5 times more abrasion-resistant than ordinary painted panels, maintaining their appearance even in high-traffic areas.

Another major advantage of UV panels is their environmental and health benefits. While traditional decorative materials often contain high levels of volatile organic compounds (VOCs), UV panels emit virtually no harmful gases during the curing process. The UV coating used in UV panels contains no harmful substances like formaldehyde and benzene, and after curing, they are completely non-toxic and odorless, meeting national E0 environmental standards. They are particularly suitable for locations with high indoor air quality requirements, such as children's rooms and hospitals.

- Comparison of UV Panels with Traditional Decorative Materials

Compared to traditional decorative materials, UV panels offer significant advantages in many areas. Compared to ordinary painted panels, UV panels offer a higher surface hardness and greater wear resistance, without the common defects of paint, such as sag and orange peel. Regarding stain resistance, UV panels' dense surface resists stain penetration, making cleaning and maintenance easier. Compared to fireproof panels, UV panels offer a wider range of decorative effects, enabling a variety of visual effects, including high gloss, matte, and metallic, to meet diverse design requirements.

From an economic perspective, while the initial purchase cost of UV panels may be slightly higher than some traditional materials, their longevity, low maintenance, and lack of frequent refurbishment make them more cost-effective over time.

In terms of construction efficiency, pvc wall marble plates are manufactured using standardized methods, resulting in precise dimensions and easy installation, significantly reducing construction time. Traditional decorative materials such as stone and solid wood often require on-site cutting and sanding, which is not only inefficient but also generates significant dust pollution. UV panels, on the other hand, utilize a modular installation method, ensuring both cleanliness and efficiency.

- Applications of UV Panels

UV panels are widely used in home decoration. In the kitchen, UV board cabinet doors resist oil smoke and can be easily wiped clean. Bathroom walls using UV board effectively resist moisture and mildew. Living room TV walls decorated with UV board enhance the space's quality while also being easy to clean and maintain.

Commercial spaces demand higher levels of material durability and aesthetics, which is precisely where UV board excels. In public spaces like hotel lobbies, shopping malls, and office buildings, UV board walls and columns maintain a pristine appearance over time. The restaurant industry uses UV board partitions, which are both aesthetically pleasing and easy to disinfect and clean. In display counters and specialty stores, the high-gloss surface of UV board effectively enhances product display.

Specific scenarios. For example, hospitals and laboratories require a highly clean, antibacterial environment, and the seamless surface of UV board prevents bacterial growth. Kindergartens and schools use UV board, ensuring safety and environmental protection while resisting children's graffiti. High-end clubs and showrooms seek unique design effects, and UV board's rich selection of colors and textures perfectly meet these needs.

- How to Choose High-Quality UV Panels

When purchasing marble pvc plates, first consider the quality of the substrate. High-quality UV panels should use an E0-grade environmentally friendly substrate with uniform density and no obvious defects. The quality of the substrate can be determined by observing a cross-section of the panel; a high-quality substrate has fine particles and a dense structure. Secondly, consider the surface treatment process. A good UV panel should have a smooth, even surface, free of bubbles, impurities, or scratches, and a uniform gloss.

Tips for identifying UV panel quality include: lightly scratching the surface with a fingernail; high-quality UV panels should leave no visible marks; painting with a marker should completely wipe clean; and observing the surface from the side should reveal a uniform reflective effect with no wavy or warping.

The prices of UV panels vary widely on the market, so consumers should choose based on their specific needs. For ordinary home decoration, choose mid-priced products, focusing on the environmental friendliness of the substrate and surface hardness. For commercial spaces or demanding applications, choose high-end products, focusing on wear resistance and special properties. It is important to note that underpriced UV panels are likely to compromise on substrate or coating quality and are not recommended.

- UV Panel Installation and Maintenance Guide

UV panel installation requires certain expertise, but is simpler than many traditional materials. Wall installation typically involves gluing or fixing with studs, ensuring the substrate is flat and dry. Furniture installation often utilizes flush mounting or hardware connections. During installation, avoid hard objects impacting the surface, and allow for adequate expansion joints at joints. It's important to note that while UV panels offer excellent performance, they are not recommended for direct outdoor exposure, as prolonged exposure to sunlight and rain will shorten their service life.

In terms of daily maintenance, UV panels are very easy to clean. For general cleaning, simply wipe with a soft, damp cloth. For stubborn stains, use a neutral detergent; avoid using strong acids or alkalines, or harsh cleaning tools like steel wool. Avoid scratching the surface with sharp objects.

Treating Common Problems: Minor scratches can be treated with a special repair paste. Cracks in joints should be promptly repaired with a matching sealant to prevent moisture intrusion. Localized damage can be professionally repaired, while extensive damage is recommended for complete panel replacement. Regularly check for loose fasteners, especially for suspended UV panels.

- UV Panel Market Prospects and Development Trends

With growing environmental awareness and rising aesthetic standards, the UV panel market is experiencing rapid growth.

In terms of technological innovation, UV panels are becoming increasingly multifunctional. New products such as antibacterial UV panels, self-cleaning UV panels, and anti-fingerprint UV panels are becoming increasingly popular. Surface effects are also becoming more diverse, ranging from traditional high-gloss to matte, metallic, and 3D effects. In terms of production, the application of digital printing technology enables UV panels to achieve more complex and realistic patterns and textures, meeting personalized customization needs.

Environmental policies are also a key driver of marble pvc board development. As national environmental standards become increasingly stringent, traditional highly polluting decorative materials will be gradually phased out. UV panels, however, aligning with the concept of green development, are expected to receive greater policy support.

- Conclusion

As a new decorative material that combines aesthetics, practicality, and environmental protection, UV panels are changing traditional perceptions of interior decoration. Its superior physical properties, diverse decorative effects, and convenient installation make it an ideal choice for modern decoration. Whether it's home renovation or commercial space design, UV panels offer high-quality solutions. With continuous technological advancements and market development, UV panels are poised to become a mainstream product in the future decorative materials market, creating a better and healthier living environment for people.