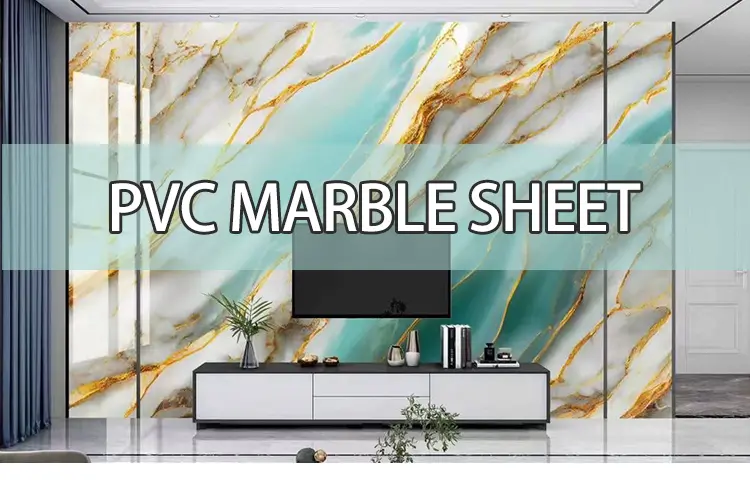

User Gide——Uv Marble Sheet

- Definition and composition of UV marble board

UV marble board is a new type of decorative board made of polymer composite material as the base material and processed by advanced UV curing technology. Its core structure consists of three parts:

⚡ Base material layer: usually high-density PVC or acrylic material is used to ensure the stability and strength of the board.

⚡ Decorative layer: realistic marble texture is presented through high-definition printing technology.

⚡ Protective layer: UV light curing coating, giving the board excellent surface performance.

- Production process and technical advantages

1. Modern manufacturing process

⚡ Substrate pretreatment: Use precision sanding equipment to ensure surface flatness.

⚡Surface coating: Customize product surfaces of different materials and different color patterns according to customer needs.

⚡ UV curing: German UV light curing system achieves instant hardening.(3-5 seconds to complete curing)

⚡ Quality inspection: Fully automatic optical inspection system controls product quality.

2. Core technology advantages

⚡ Environmental performance: Zero formaldehyde addition, VOC emissions are 50% lower than the national standard, no odor.

⚡ Production efficiency: more than 300% higher than traditional processes.

- Excellent product characteristics

Physical properties

⚡ Surface hardness: Reach 4H pencil hardness (ASTM D3363 standard)

⚡ Abrasion resistance: After 5000 turns of wear test, it still maintains more than 90% gloss and has good wear resistance

⚡ Weather resistance: Passed 2000 hours of QUV accelerated aging test

Practical performance

⚡ Anti-fouling level: Reach the highest level 5 (GB/T 3810.14 standard)

⚡ Fireproof performance: B1 grade flame retardant material (GB 8624-2012 standard), flame retardant and self-extinguishing

⚡ Dimensional stability: deformation <0.3mm/m when the temperature changes by 20℃, and it will not deform easily after being put on the wall

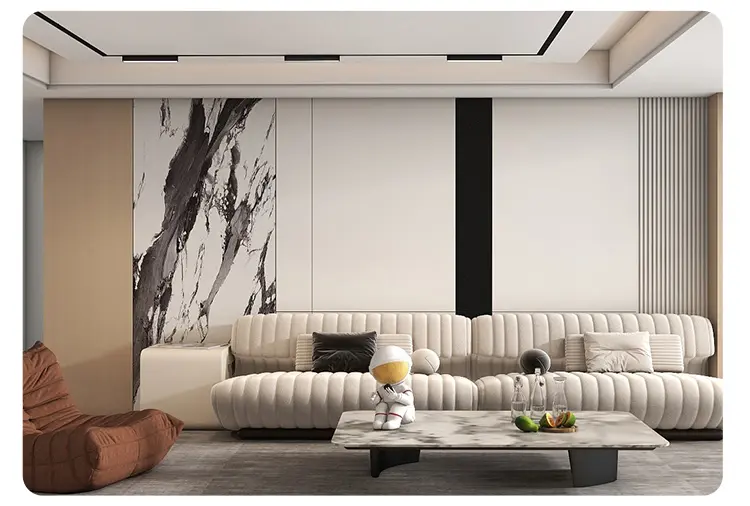

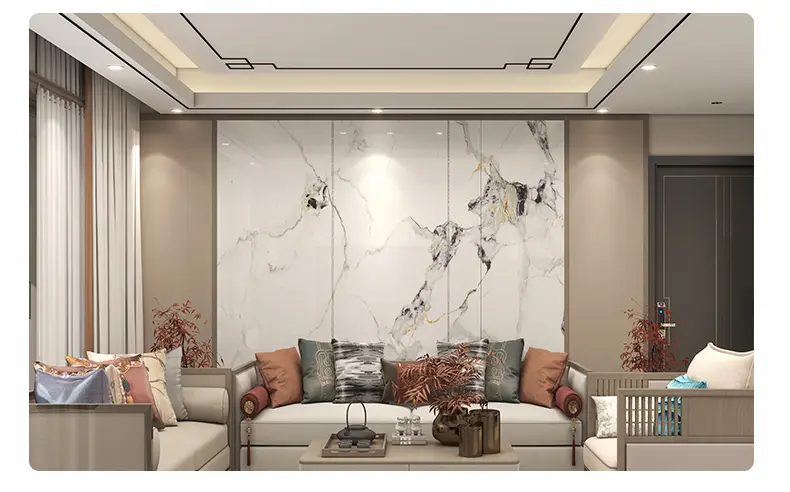

Decorative performance

⚡ Texture restoration: the decorative effect is comparable to natural marble, with clear texture

⚡ Gloss selection: There are two options: high gloss and matte, and matte is divided into two types: UV-containing paint and non-UV-containing paint

⚡ Color system: There are hundreds of color patterns that can be customized. In addition, 3D printing can be performed according to the photos provided by the customer (the cost is relatively high)

- Diversified application scenarios

High-end residential area

⚡ Integrated kitchen system: The integrated countertop made of oil-proof marble pvc uv panels not only has excellent oil-proof performance, but its seamless splicing process can effectively prevent the growth of bacteria. With the hidden drainage design, it creates a modern kitchen space with both aesthetics and functionality.

⚡ Bathroom space solution: The integrated UV marble slab washbasin completely solves the water seepage problem of traditional bathroom space through special waterproof treatment technology, and provides a variety of texture options to meet different style requirements from simple to light luxury.

⚡ Smart background wall system: Using 3D printing technology to process UV marble slabs into three-dimensional decorative walls, invisible lighting systems and smart touch functions can be integrated to achieve a perfect fusion of decorativeness and technology.

Commercial space application

⚡ Hotel art lobby: The UV marble slab wall system using patented splicing technology can achieve up to 8 meters of seamless continuous paving, and with special optical treatment technology, it presents dynamic visual effects at different light angles to enhance the artistic value of the space.

⚡ Brand image display system: Modular UV marble slab display stand tailored for high-end retail brands, supporting fast disassembly and personalized pattern printing, perfectly presenting the brand tone, and the transformation cycle of a single store can be shortened to 48 hours.

⚡ Smart office partition: The intelligent marble pvc uv partition system with integrated conductive layer can realize touch operation while maintaining the texture of natural stone, meeting the dual pursuit of technology and aesthetics in modern office space.

Special environment application

⚡ Medical-grade antibacterial solution: UV marble slabs treated with nano-silver ion implantation technology have an antibacterial rate of up to 99.9%, which is particularly suitable for medical spaces with extremely high hygiene requirements such as operating rooms and ICUs.

⚡ Professional laboratory countertops: Corrosion-resistant UV marble slabs with specially formulated resins can resist strong acid and alkali erosion (PH value 1-14), and have excellent impact resistance (can withstand 500J impact).

⚡ Rail transit interior system: Lightweight composite UV marble panels (density ≤1.2g/cm³) have passed strict fire protection (EN45545-2 standard) and seismic tests and have been successfully used in multiple high-speed rail and subway projects.

- Green and sustainable development advantages

1. International authoritative environmental certification

- GREENGUARD Gold Certification: The world's most stringent indoor air quality standard, ensuring that the product VOC emissions are less than 0.022mg/m³

- French A+ certification: Passed 28-day closed chamber testing, formaldehyde emission ≤0.004mg/m³

- EU RoHS compliance: Completely bans 6 types of hazardous substances such as lead and cadmium, in line with Directive 2011/65/EU

2. Low-carbon environmental protection practice

- Energy-saving production: Using a photovoltaic power supply system, the unit product energy consumption is only 2.3kWh/㎡, which is 85% lower than traditional processes

- Green logistics: Product density 1.2-1.5g/cm³, transportation carbon emissions reduced by 67%

- Long-term use: Verified by accelerated aging tests, the service life is 15-20 years, reducing the frequency of replacement

3. Circular economy system

- Waste recycling: Factory closed-loop recycling system, waste can be used as high-strength composite Building Materials after crushing

- Bio-based materials: 30% of the raw materials are plant fiber composite materials, which can be degraded by 80% within 5 years under natural conditions

- Recycling service: Provide professional recycling services for old boards, and the recycled materials are used in municipal projects such as road base materials

Note: All environmental data have passed SGS third-party testing and certification, and a complete life cycle assessment (LCA) report can be provided.

- Industry development trend

1. Intelligent interactive Wall Panel system

Multimodal touch technology

Adopting capacitive-pressure fusion touch solution to achieve 99.2% recognition accuracy

Supporting 10-point touch synchronous response, touch delay <8ms

Embedded intelligent system

Developing a dedicated operating system, compatible with mainstream smart home protocols

Realizing an integrated solution for wall display and control

2. Self-repair protection technology

Microcapsule self-repair system

Adopting a double microcapsule structure (repairing agent + catalyst)

Complete more than 90% of scratch repair within 3 hours at room temperature

The number of cycle repairs can reach more than 50 times

Nano-enhanced coating

Adding graphene nanosheets to improve the mechanical strength of the coating

The surface hardness reaches 6H pencil hardness

Abrasion resistance increased by 300%

3. Intelligent optical Wall Panels

Dynamic color display technology

Adopting electrochromic materials, supporting 16.7 million color display

Color switching response time <1 second

Energy consumption is 60% lower than traditional solutions

- Conclusion

As an innovative product in the field of decorative materials, marble type sheets perfectly combine the aesthetic value of natural stone with the technological advantages of modern materials. Its excellent performance, flexible customization capabilities and significant environmental protection characteristics are reshaping the standards of the architectural decoration industry. With the continuous breakthrough of technology and the continuous expansion of application scenarios, UV marble slabs will surely become the mainstream choice for future space design.

We sincerely invite you to visit the experience center to experience the extraordinary quality of UV marble slabs. The professional consultant team will provide you with:

Free sample service

Project customization plan

Technical support guarantee

Full-cycle service tracking

Let us explore the infinite possibilities of decorative materials together and create a more valuable space experience.

FAQs

1.How can we guarantee quality?

We provide complete pre-sales and after-sales services while ensuring product quality. All products will have been strictly

quality test before packing.

2.Why should you buy from us not from other suppliers?

We have our own factories,and have a wide range of products,we offer customized services to ensure your complete satisfaction.

Fast shipping, never delayed, sample orders are shipped within 3 days, 20GP/40GP orders are shipped within 15--20 days.

3.Can I send a sample? Is it free?

Yes,samples can be provided to you free of charge, you only need to pay the sample delivery charge.

Free samples

As more and more people choose this product, import and export have also increased their efforts. In order to help people who are cooperating for the first time and trying to sell this product for the first time feel its value, we have launched a free sample activity. If you need it, please feel free to contact us, and we will have a professional service team to connect with you. There is no doubt that marble sheet uv wall panel will become a hot existence in the decorative materials industry!