Understanding the Lifespan of PVC Marble Sheets: What to Expect & How to Maximize Durability

Table of Contents

Key Material and Design Factors That Influence Longevity

Typical Service Life / Lifespan Ranges

Environmental & Installation Influences on Durability

Best Practices to Prolong the Lifespan

PVC Marble vs Other Surface Materials: Lifespan Comparison

Real-World Use Cases & Longevity Lessons

Emerging Trends & Innovations in Durability

1. What Are PVC Marble Sheets?

PVC marble sheetsare decorative composite panels made of polyvinyl chloride (PVC) with a printed or laminated marble pattern. They are used widely for Wall Cladding, ceiling linings, showers, kitchen backsplashes, partitions, and decorative features. Compared to natural stone or tile, they are lighter, easier to handle, lower in cost, and more forgiving in terms of installation.

Their appeal lies in combining aesthetics (simulating marble veining and texture) with practical benefits: water resistance, low maintenance, easy cleaning, and flexibility in design.

2. Key Material and Design Factors That Influence Longevity

The lifespan of a PVC marble sheet depends heavily on its intrinsic properties and construction. Here are the most critical factors:

- PVC quality and formulation: High-grade PVC, often with stabilizers, UV inhibitors, and additives, resists degradation better.

- Surface protection / wear layer: Many premium sheets include a protective coating (e.g. UV-cured layer, scratch-resistant film) which shields the decorative layer.

- Sheet thickness: Thicker panels can better resist impact, bending, warpage, or deformation under stress.

- UV stabilization: For applications exposed to sunlight, UV-resistant or UV-stabilized variants slow down color fading and brittleness over time.

- Adhesives, backing, and support structure: The bonding system and substrate quality matter — poor adhesion or substrate movement can cause delamination or warping.

- Edge sealing and joints: How well edges, joints, seams are sealed against moisture or infiltration plays a big role in lifespan.

Manufacturers, in fact, often quote lifespans in terms of years provided certain protective measures are applied.

3. Typical Service Life / Lifespan Ranges

When a PVC marble sheet is well-made, properly installed, and maintained under moderate conditions, you can expect:

- Indoor use (protected from direct UV and extreme temperature swings): 10 to 20 years is a reasonable range.

- More conservative estimates for typical installations (without optimal conditions): 5 to 15 years.

- In UV or sun-exposed settings (without strong UV stabilization): degradation may begin after 8–12 years.

- In ideal indoor, low-stress situations, PVC sheets (more generally) have been suggested to last 20 to 30 years or more.

Thus, rather than a single fixed figure, your life expectancy will fall somewhere within those bands depending on conditions.

4. Environmental & Installation Influences on Durability

Several external and installation-related factors can accelerate aging or failure — or, conversely, help prolong life.

| Factor | Impact | Notes / Mitigation |

| Sunlight / UV exposure | Causes fading, discoloration, surface embrittlement | Use UV-resistant coatings or shaded installations |

| Temperature fluctuations | Expansion/contraction can induce stresses, warping | Leave expansion gaps, use flexible adhesives |

| Humidity / water infiltration | Moisture seeping under sheets can weaken adhesion or cause warping | Good sealing of edges, joints, proper waterproofing |

| Mechanical stress / impact | Scratches, dents, chips may appear | Avoid heavy impact, shield areas with pads or reinforcement |

| Chemical agents / cleaning agents | Harsh solvents or acids degrade surfaces | Use mild, pH-neutral cleaners; avoid aggressive chemicals |

| Poor installation / substrate issues | Uneven substrate, inadequate prep, wrong adhesive lead to failure | Proper surface prep, flat substrate, suitable adhesives |

| Thermal / heat exposure | Proximity to hot appliances may cause discoloration or softening | Maintain distance, use insulation or thermal barriers |

Installation is especially crucial: even a top-tier Pvc Panel will underperform if installed incorrectly (e.g. inadequate sealing, improper adhesives, substrate movement, poor alignment).

5. Best Practices to Prolong the Lifespan

To ensure your PVC marble sheets last as long as possible, apply these practical tips:

- Use high-grade material — select panels with UV protection, thick wear layers, and quality formulations.

- Seal all joints and edges — apply good sealant to borders and connections, especially in bathrooms or wet zones.

- Ensure proper substrate preparation — the wall or backing must be flat, stable, dry, and clean.

- Choose the right adhesive & installation method — use adhesives rated for PVC, allow for expansion gaps.

- Regular cleaning and gentle care — wipe with soft cloths, use mild detergents; avoid abrasives or strong solvents.

- Protect from heat / abrasion — avoid dragging sharp objects, maintain distance from hot appliances.

- Consider protective films or coatings — especially in sun-exposed or high-use zones.

- Inspect periodically and repair early — small cracks, loose edges, peeling edges should be remedied before they worsen.

By following these practices, many installations can achieve toward the upper end of the lifespan range.

6. PVC Marble vs Other Surface Materials: Lifespan Comparison

Let’s compare PVC Marble Sheets to alternative finishing materials in terms of longevity, cost, maintenance, and trade-offs:

| Material | Typical Lifespan | Maintenance | Cost | Strengths / Weaknesses |

| Natural Marble / Stone | 50+ years (often decades or centuries) | High — sealing, polishing, cleaning | High | Very durable, prestigious, but expensive and heavy |

| Ceramic / Porcelain Tile | 20–30 years (or more) | Moderate — grout maintenance, cleaning | Moderate to High | Hard, stable, well-tested |

| Laminate Panels / HPL | 5–15 years (depending on quality) | Moderate | Low to Medium | Good aesthetics, but more vulnerable to moisture or edge damage |

| PVC Marble Sheets | ~10–20 years (in good conditions) | Low | Low to Medium | Lightweight, waterproof, easy install; less durable than stone |

In other words, PVC marble offers a balance: more longevity than typical laminates in wet zones, but far lower cost and complexity than natural stone.

7. Real-World Use Cases & Longevity Lessons

Here are illustrative scenarios (adapted) that highlight how lifetime performance plays out in practice:

- Bathroom wall cladding (residential): A 3 mm PVC marble panel installed with good sealing in a moderate-humidity home might still look good after 12–15 years.

- Restaurant kitchen splashback: A 5 mm variant in a commercial kitchen environment may begin showing wear or discoloration after 10–12 years due to heat, cleaning agents, steam.

- Outdoor facade decorative cladding: In high-UV climates, a non-UV-stabilized panel might degrade visibly (fading, chalking) after 8–10 years; with UV-treated panels, that might stretch to 12–15 years or beyond.

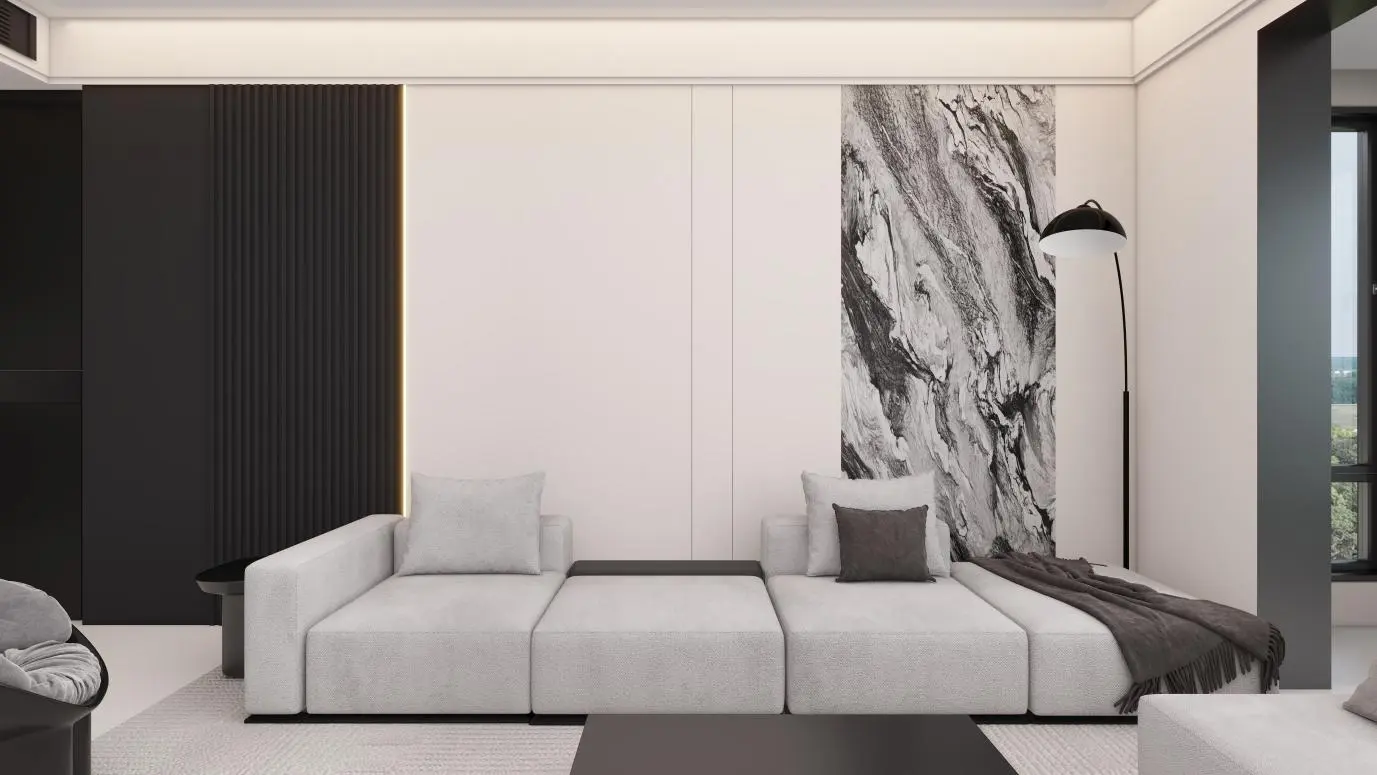

- Dry indoor feature wall: In a living room or bedroom away from direct sun, panels installed well could maintain aesthetics for 18–20 years or more.

From these examples, you see that context — exposure, maintenance, material grade, and installation — shifts the effective life quite a bit.

8. Emerging Trends & Innovations in Durability

To push PVC marble sheet longevity even further, manufacturers and R&D are working on:

- Advanced UV / anti-fading coatings — improved coatings that better resist sunlight-induced degradation

- Scratch- and abrasion-resistant surface layers — tougher top films or treatments

- Self-healing or self-cleaning coatings — surfaces that reduce micro-scratches or resist staining

- Improved composite formulations — optimized resins, fillers, and stabilizers

- Better fastening systems / click-in panels — reducing adhesive failure risk

- Eco- or bio-based PVC alternatives — to reduce environmental impact while maintaining durability

These advances may gradually raise the upper lifespan limit over time (e.g. pushing more installations comfortably into the 20+ year range).

9. Final Thoughts

- The expected lifespan of a PVC marble sheet is not a fixed number — it generally spans from 5 to 20 years, with 10–20 years being a realistic range for quality installations under favorable conditions.

- The primary determinants are material grade, protective coatings (especially UV resistance), installation quality, and environmental exposure.

- Even the best panels can fail prematurely if installation or sealing is poor, or if they are subjected to undue stress, moisture intrusion, or heat.

- With careful selection, proper installation, and regular maintenance (gentle cleaning, edge sealing, repair of small defects), many projects will reach or exceed the higher end of their expected service life.