PVC Marble Sheets: A Modern Alternative to Natural Stone for Stylish, Affordable Interiors

Table of Contents

- Introduction

- Understanding PVC Marble Sheets

- Strengths of PVC Marble Panels

- Common Usage Scenarios

- Market Dynamics & Global Demand

- Final Thoughts

- Why Source from a Reliable Chinese Manufacturer

1. Introduction

In contemporary interior design, striking the balance between elegance, cost, and practicality is a continual challenge. Natural marble delivers prestige but burdens projects with high cost, weight, and maintenance. In response, PVC marble sheets (also sometimes called PVC marble panels or PVC-based decorative stone panels) have surged in popularity as a lightweight, affordable, and aesthetically pleasing alternative.

2. Understanding PVC Marble Sheets

Pvc Marble Sheets are decorative panels made of polyvinyl chloride (PVC) compounds, calcium carbonate (or other fillers), stabilizers, pigments, and protective coatings. A high-resolution printed film (or UV-cured print) replicates marble veining, while a top surface layer offers protection (scratch resistance, UV resistance).

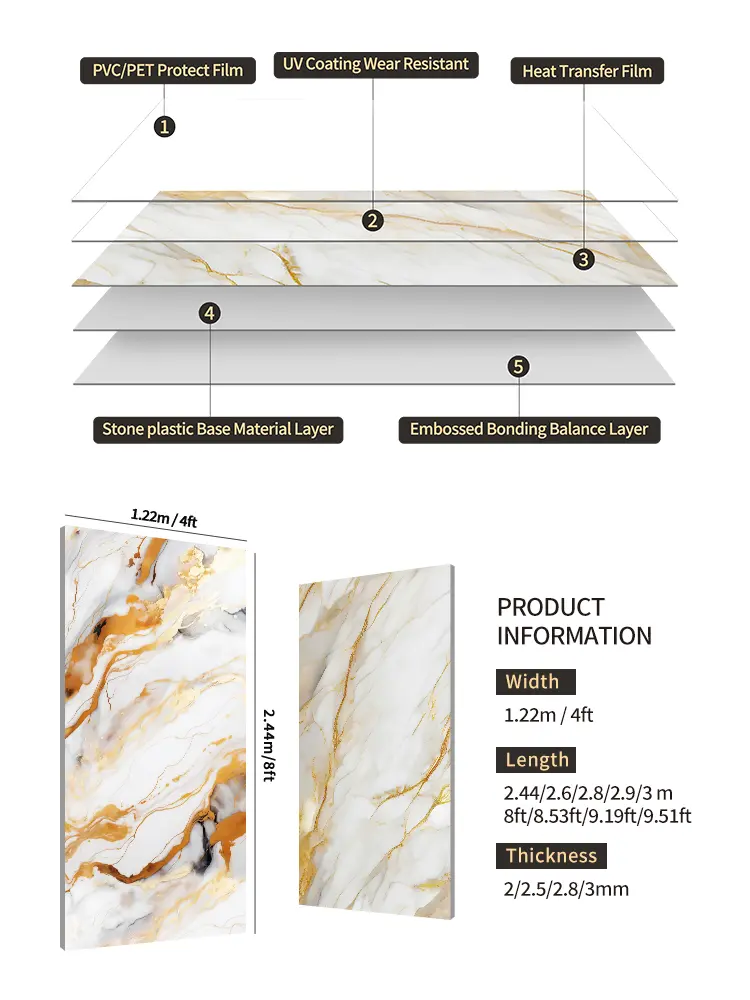

Typical structure

- Core / substrate: rigid or semi-rigid PVC + filler (e.g. CaCO₃)

- Printed decorative film: high-definition marble or stone pattern

- Protective layer / UV coating: resists abrasion, yellowing, UV exposure

Thickness often ranges from 2 mm up to 3 mm (or more in specialty lines). Standard sheet dimensions are similar to wallboard sizes, e.g. 1220 × 2440 mm (4×8 ft), though custom sizes are common.

Because the core is polymer-based, the panels are far lighter than natural stone or tile slabs, which makes handling and installation much easier.

3. Strengths of PVC Marble Panels

Below are the key advantages that drive their adoption:

3.1 Cost advantages

- The raw materials (PVC resin, filler) are substantially less expensive than quarried marble or granite.

- Lower transportation and handling costs due to lighter weight.

- Reduced labor cost: installation is simpler and faster, needing fewer specialized skills.

- Overall total project cost is often cut by 30–60% compared to using real stone in many cases.

3.2 Lightweight & faster installation

- A PVC marble sheet typically weighs much less than stone slabs, easing handling, shipping, and installation.

- Many panels support interlocking edges, adhesive or clip systems, and can be cut on site with basic tools (knife, saw).

- Installation times are significantly shorter — less demolition, no heavy lifting or structural reinforcement in many renovation cases.

3.3 Waterproof, moisture-resistant & hygienic

- PVC is non-porous, so it does not absorb water. This makes it suitable for humid or wet areas like bathrooms, kitchens, laundries, and basements.

- Because it does not harbor moisture, it resists mold, mildew, and staining, supporting cleaner, hygienic environments.

3.4 Low maintenance & ease of cleaning

- No sealing or polishing is needed (unlike natural marble).

- Routine cleaning is as simple as wiping with a damp cloth and mild detergent.

- Surfaces resist stains, grease, and grime thanks to the smooth protective layer.

3.5 Design flexibility & aesthetics

- Advanced printing/lamination techniques allow for high-fidelity replication of marble vein patterns (Carrara, Calacatta, Nero Marquina, etc.).

- Custom patterns, colors, textures, and finishes (gloss, matte) are often available.

- Because the pattern is printed, uniform appearance across large areas is easier (less variation than natural stone).

3.6 Safety / Fire performance

- Many quality PVC marble sheets incorporate flame-retardant additives to achieve certain fire classes (e.g. B1) to slow flame spread.

- In public and commercial interior spaces, fire safety is a key consideration; good Pvc Panels help meet those regulations.

3.7 Durability / Lifespan

- The UV protective coating helps resist fading, discoloration, and surface aging under normal indoor conditions.

- With proper installation and care, many panels maintain their appearance for 10–15 years or more.

- Scratch, abrasion, and impact resistance (for light to moderate use) is acceptable in interior settings.

4. Common Usage Scenarios

Here’s where PVC marble sheets are most effectively used:

| Application Area | Typical Uses | Why It Works Well |

| Residential | Accent walls, TV feature walls, bathroom walls & surrounds, false ceilings, kitchen backsplashes (away from stove) | Lightweight, moisture-resistant, easy installation |

| Hospitality / Hotels | Lobbies, corridors, reception walls, guest room walls | High-end marble look on budget, uniform visual style |

| Commercial / Office | Meeting rooms, reception, corridors, elevator lobbies | Durable, low maintenance, quick installation |

| Restaurants / Cafés | Feature walls, bar fronts, decorative ceilings | Moisture resistance, easy to clean |

| Retail / Shopping Malls | Display walls, feature zones, signage panels | Custom designs, changeable, visual impact |

| Healthcare / Clinics | Reception walls, partition walls | Hygienic, easy to sanitize |

| Institutional / Public Spaces | Waiting rooms, corridors, public restrooms | Affordable decorative finish with easier upkeep |

Because these panels can be readily cut and shaped, they fit around switch boxes, plumbing penetrations, irregular surfaces, and curved walls with relative ease (compared to stone).

While they are great for interiors, they are generally unsuitable for outdoor façades or exposed exterior walls due to UV and weather exposure.

5. Market Dynamics & Global Demand

The PVC uv marble panel market has been expanding steadily. Key drivers and trends include:

- Rising demand for affordable luxury: Many developers and designers prefer materials that deliver a marble aesthetic at lower cost.

- Growth of renovation, retrofit, and interior remodeling: In mature markets, more projects focus on interior upgrades rather than new builds.

- China as leading producer and exporter: China dominates manufacturing in this sector due to mature production capabilities, customization capacity, and cost competitiveness.

- Design customization: Buyers increasingly demand unique patterns, textures, and branding in marble-look finishes.

- Sustainability push: Manufacturers emphasize lead-free, low-VOC formulations, recyclable components, and stricter compliance with environmental certifications.

- Technology upgrades: Higher-end printing, UV coating, and composite core technologies improve durability and visual realism.

Market forecasts suggest compound annual growth rates (CAGR) of 5–8% in many regions over the next 5 years, with particular expansion in Asia, Latin America, and parts of the Middle East as interior finishing standards rise.

6. Final Thoughts

PVC uv marble sheets offer a powerful blend of visual elegance, practicality, and cost efficiency — making them a compelling choice for many interior scenarios that demand both style and affordability. They shine in moisture-prone, budget-conscious, or retrofit settings where full natural stone would be impractical.

Nonetheless, they are not flawless. Their lower heat tolerance, inability to fully replicate the tactile quality of stone, variability in manufacturer quality, and repair limitations are real trade-offs. The key to success is specifying the right grade of panel for the environment, carefully managing installation, and sourcing from a credible supplier.

7. Why Source from a Reliable Chinese Manufacturer

If you’re looking to import at scale, sourcing from a competent Chinese PVC marble sheet factory can unlock advantages:

- Competitive pricing — due to economies of scale and mature supply chains.

- High customization capability — Chinese manufacturers often accommodate custom sizes, patterns, and private-labeling.

- Strong export infrastructure — many factories are experienced exporters with packaging, logistics, and quality control systems for global clients.

- Access to innovation — many Chinese firms invest in advanced printing, UV curing, composite cores, and eco-PVC formulations.

- Supply chain integration — they may control PVC resin sourcing, printing, coating, and finishing in-house, reducing lead times and risk.