PVC Marble Panels: A Modern Alternative Transforming Interior Design

Table of Contents

- Understanding PVC Marble Panels

- Core Components and Their Functions

- Key Advantages of PVC Marble Panels

- Where PVC Marble Panels Are Used

- Panel Size Options and Thickness Guide

- How to Install PVC Marble Panels

- Care and Cleaning Tips

- Market Outlook and Industry Growth

- How to Select a Reliable Manufacturer

- Conclusion

During the past decade, the Interior Decoration industry has shifted dramatically toward lightweight synthetic materials that can replicate the appearance of natural stone. Among these new materials,PVC marble panels—also referred to as PVC decorative boards or synthetic Marble Sheets—have rapidly emerged as one of the most practical and visually appealing options. They bridge the gap between aesthetics, performance, and cost-efficiency, making them suitable for both large-scale construction and small residential remodeling projects.

This article explores PVC marble panels from multiple perspectives—their composition, benefits, installation process, and rising global demand—while offering guidance for choosing a reputable manufacturer.

Understanding PVC Marble Panels

PVC marble panels are engineered sheets made from polyvinyl chloride, blended with stabilizers, plasticizers, mineral additives, and surface films that deliver stone-like patterns. The goal is simple: create the luxurious appearance of marble while avoiding the high cost, extreme weight, and maintenance challenges of natural stone.

How It Differs from Natural Marble

| Feature | Natural Marble | PVC Marble Panels |

| Weight | Heavy | Lightweight |

| Installation | Requires professional handling | DIY-friendly |

| Maintenance | Needs sealing & polishing | Wipe-clean surface |

| Moisture Resistance | Absorbs water | Waterproof |

| Cost | Expensive | Affordable |

Pvc Marble Boards are available in an extensive collection of patterns—glossy marble, matte stone grain, geometric print, metallic finishes, and even wood-texture hybrids. This design flexibility allows architects to match specific interior themes without relying on rare or expensive natural stone.

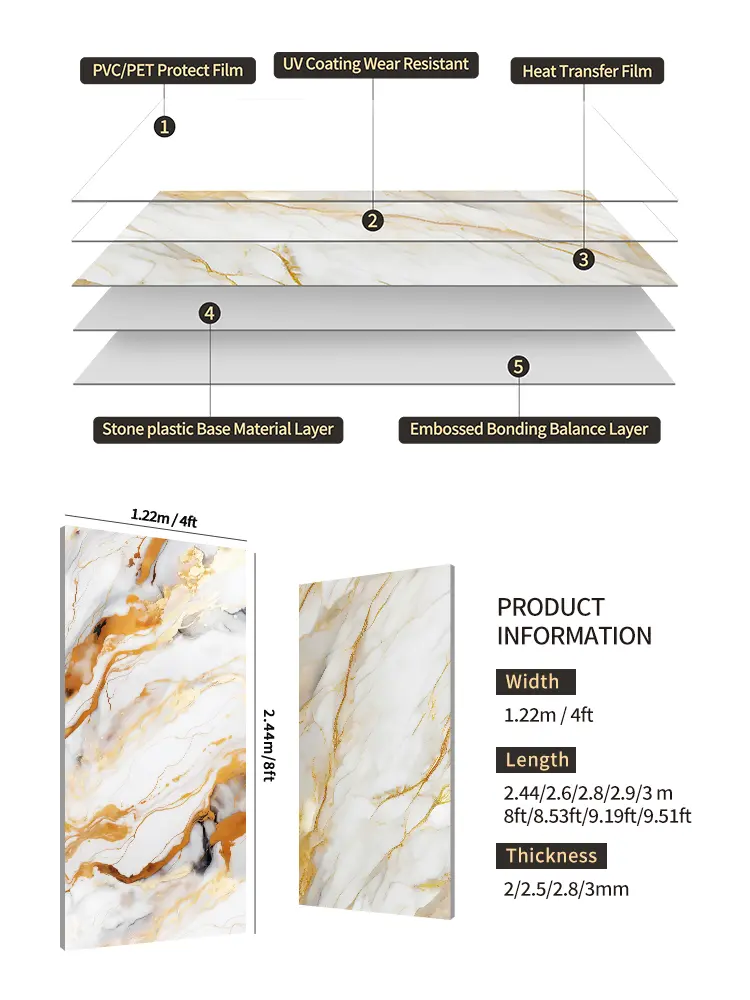

Core Components and Their Functions

Even though manufacturers may vary in formulas, most PVC marble panels contain the following:

- PVC Base Layer: Provides structural rigidity and resistance to impact.

- Calcium Powder or Mineral Fillers: Adds density and strengthens the panel.

- Plasticizers: Improve flexibility and prevent brittleness.

- UV Stabilizers: Protect against discoloration in bright indoor environments.

- Surface Film (Laminated or Hot-Pressed): Creates the realistic marble effect and protects the surface from scratches and stains.

The advanced printing technologies used today—such as 4D and 5D multi-layer imaging—make modern PVC marble panels almost indistinguishable from genuine marble at a glance.

Key Advantages of PVC Marble Panels

PVC marble panels have become widely popular for several compelling reasons. Below are the most notable benefits that explain their expanding market share.

- Quick and Hassle-Free Installation

A major reason they attract contractors and home renovators is their simplicity. Most panels can be installed using adhesive glue, and they require no grouting, polishing, or heavy tools.

- Budget-Friendly Without Compromising Appearance

They offer the look of premium marble at a fraction of the cost. This advantage is especially valuable in retail design, hospitality environments, and large apartment developments where design needs to remain consistent yet economical.

- Water and Moisture Resistance

Unlike natural marble that can absorb water and stain, PVC marble panels are 100% water-resistant. This makes them suitable for:

- Bathroom walls

- Shower enclosures

- Kitchen backsplashes

- Laundry rooms

- Basement spaces

- Low Maintenance Requirements

The surface does not require special cleaning agents. A mild detergent is enough to maintain its glossy finish.

- Fire-Retardant and Chemical-Resistant

High-quality panels include fire-retardant additives and are resistant to household chemicals, mild acids, and oils—a major advantage in restaurants, laboratories, and medical facilities.

- Large Variety of Designs

With hundreds of patterns, gloss levels, and textures, PVC marble sheets offer far more choices than natural stone suppliers typically provide.

Where PVC Marble Panels Are Used

The applications of PVC marble sheets extend across multiple industries. Below is a categorized overview:

Residential Use

- TV background walls

- Bedroom feature panels

- Bathroom ceilings

- Wardrobe doors

- Decorative hallways

Commercial Spaces

- Boutique stores and retail counters

- Hotel lobbies and corridors

- Restaurant interiors

- Corporate offices and meeting rooms

Industrial & Institutional Settings

- Clinics and hospitals (due to hygienic surface)

- Laboratories requiring chemical resistance

- Production environments where washable walls are needed

Renovation and Remodeling

Lightweight panels greatly reduce labor compared to ceramic tiles or marble slabs, making them ideal for building upgrades.

Panel Size Options and Thickness Guide

Although sizes vary by manufacturer, the most common formats include:

- 1220 × 2440 mm (4 ft × 8 ft)

- 1220 × 2800 mm

- Height-extended sheets for full wall coverage

Typical thickness selections:

- 2.5–3 mm: Decorative walls, ceilings

Some manufacturers offer custom cuts to match interior design specifications.

How to Install PVC Marble Panels

The installation process is simple but must be done correctly for long-term durability.

Step-by-Step Overview

- Prepare the Wall

- Ensure the surface is dry, clean, and level.

- Cut the Panels

- Use a fine blade saw or cutting knife to trim panels to size.

- Apply Adhesive

- Spread PVC-compatible adhesive evenly across the back.

- Align and Press

- Firmly press panels against the wall to remove trapped air.

- Fix With Screws (Optional)

- For heavy-duty installations, additional mechanical fastening helps.

- Seal Edges

- Apply silicone or PVC trims to enhance moisture protection.

Care and Cleaning Tips

PVC marble panels require minimal care, but the following practices extend their lifespan:

- Clean with mild cleaners; avoid abrasive sponges.

- Protect surfaces from extreme heat sources.

- Do not use sharp objects directly on the surface.

- Install ventilation in wet areas to reduce humidity buildup.

Market Outlook and Industry Growth

The global demand for synthetic decorative panels continues to rise. Some drivers include:

- Increasing urban construction

- The popularity of fast renovation materials

- High-definition printing technology

- Eco-friendly production standards

- Export growth from Asian manufacturing hubs

Consumers increasingly favor materials that offer both style and practicality, placing PVC marble sheets in a strong market position.

How to Select a Reliable Manufacturer

A professional supplier should provide:

- A wide range of customizable designs

- High-density PVC formulations

- Certifications such as ISO, CE, or SGS

- Stable production capacity

- Dedicated after-sales support

Ruide, headquartered in Linyi, Shandong, is one such manufacturer known for exporting premium PVC marble panels with optional customization, competitive factory pricing, and consistent quality control.

Conclusion

PVC marble panels have redefined modern interior construction. Their light weight, realistic stone appearance, and excellent durability make them a compelling substitute for natural marble. Whether used in homes, hotels, medical facilities, or retail spaces, they offer a practical solution that balances style and performance. As technology improves, PVC marble boards will continue shaping the future of modern interior design.