A new type of environmentally friendly decorative material ——Bamboo Charcoal Wood Veneer

With people's dual pursuit of environmental protection and decorative effects, wood veneer as a new decorative material has gradually been favored by the market. However, many people wonder: Is wood veneer real wood? In fact, modern wood veneer is not limited to natural wood slices, but also includes polymer composite materials composed of environmentally friendly materials such as PVC powder and calcium powder. The surface can be covered with PVC film or PET film, which not only retains the texture of solid wood, but also has better performance and environmental protection characteristics.

- Is wood veneer real wood?

In the traditional sense, wood veneer is made of natural wood cut and planed into thin slices (usually 0.1-1mm thick), and then attached to the substrate (such as density board, plywood). It belongs to the structure of "real wood" but not all solid wood.

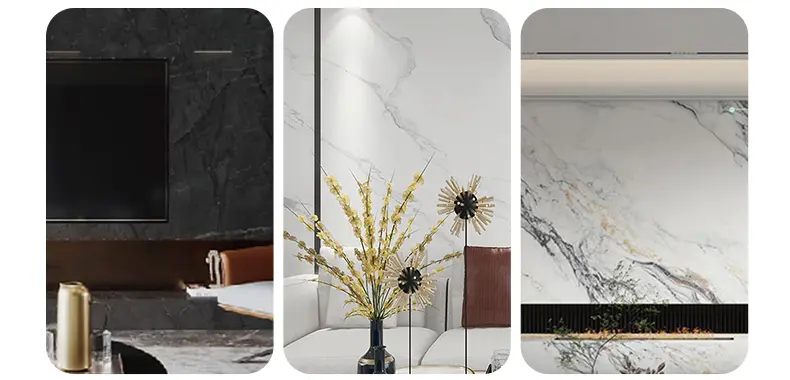

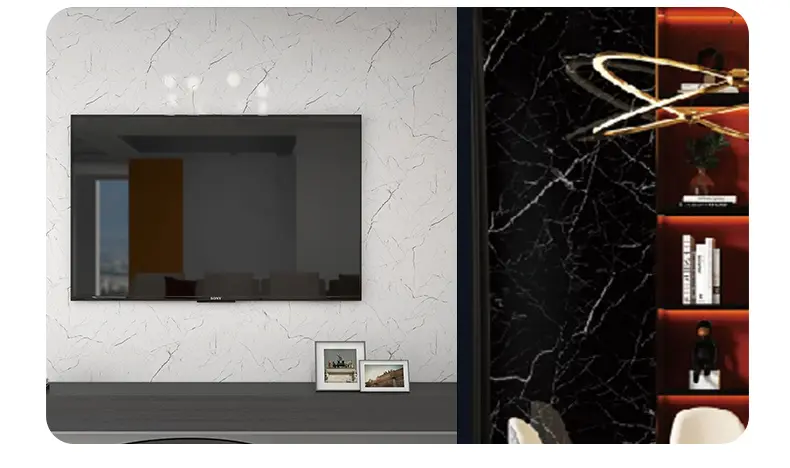

Nowadays, a new type of environmentally friendly wood veneer is popular in the market. Its base material is not wood, but a mixture of PVC powder (polyvinyl chloride) and calcium powder (calcium carbonate) is hot-pressed, and the surface is covered with PVC film or PET film. Various wood grains, stone grains and even metal textures are imitated through printing and embossing technology. This material is not natural wood, but the visual effect is realistic, and it has the advantages of waterproof, fireproof, zero formaldehyde, etc., which is more suitable for modern decoration needs.

- Composition and production process of new environmentally friendly wood veneer

1. Material composition

- Base material layer: PVC powder + calcium powder, mixed with stabilizer and plasticizer, and extruded at high temperature, with high density, moisture resistance, impact resistance and other excellent properties.

- Decoration film:

PVC film: low cost, good wear resistance, suitable for ordinary home decoration and workwear.

PET film: higher-end, with anti-scratch, high temperature resistance, and UV resistance, suitable for high-end commercial space.

2. Production process

- Mixing: PVC powder and calcium powder are mixed evenly.

- Extrusion molding: high-temperature extrusion into a board through a mold.

Surface lamination:

- Cold lamination process: Use environmentally friendly glue to laminate PVC/PET film.

- Hot pressing process: Direct lamination under high temperature and high pressure, more firmly laminated.

- Texture processing: Use 3D printing or embossing technology to imitate wood grain, stone grain, etc.

- Cutting and packaging: Cut into standard sizes as required (such as 1220×2440mm, 1220×2800mm).

- Width: Fixed 1.22 meters; general export length is 2.9 meters, other lengths can be customized for large quantities, up to 6 meters; Thickness: 5 mm/8 mm

- Product specifications and common market parameters

| Parameter | Remark | |

| Thickness | 5mm / 8mm | Balance between strength and weight |

| Surface film | PVC film / PET film | PET film is more expensive than PVC film |

| Environmental protection grade | E0 | Comply with international environmental standards |

| Fireproof grade | B1 | Flame retardant, self-extinguishing |

Installation method: More convenient than traditional wood veneer

The installation method of bamboo charcoal fiber walls varies due to their different thicknesses, mainly involving key steps such as base treatment, adhesive fixation and joint treatment. The following is a specific installation process description for 5mm and 8mm thicknesses:

- Base treatment: thickness determines the construction method

1. 5mm thick wood veneer panels-must be laid on the base

Due to the thin thickness of 5mm, it is easy to cause hollowing, deformation or cracking due to uneven base when directly installed on the wall, so leveling treatment is required first:

Applicable base materials:

✅ Wood board: good stability, suitable for home decoration walls.

✅ European pine board: strong moisture resistance, suitable for humid areas.

✅ Gypsum board: lightweight and fireproof, needs to be used with light steel keels.

✅ Flame retardant board: fire protection requirements for public places (such as hotels and offices).

2. 8mm thick wood veneer panels-can be directly installed on the wall (conditional)

8mm thickness is higher and more rigid, but the following conditions must be met:

✅ Wall flatness requirements: check with a 2-meter ruler, the gap is ≤3mm.

✅ Base strength requirements: The original wall surface is a cement mortar layer or a leveled gypsum board base.

✅ Installation process: Apply 995 type neutral glue to the back of the board and directly mount it on the wall. The splicing between the boards can be done with I-shaped lines or seamless splicing after the boards are slotted. The installer can also leave a 2mm natural seam on the edge, and there are corresponding lines at the yin and yang corners.

Eco friendly wood veneer, compose a natural poem for your home:

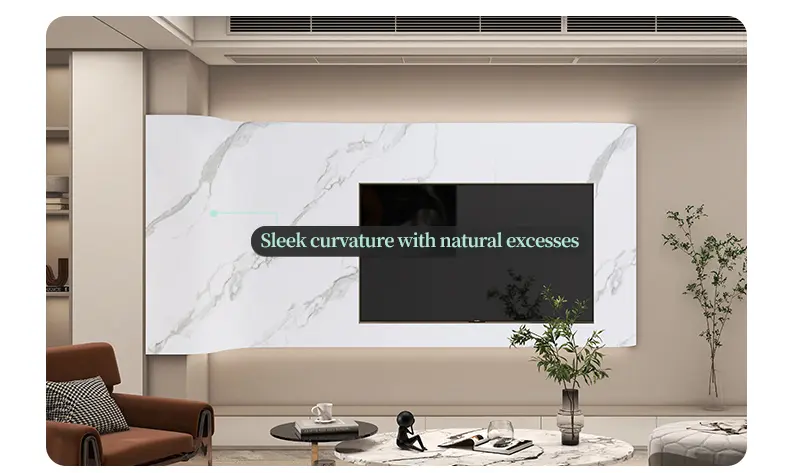

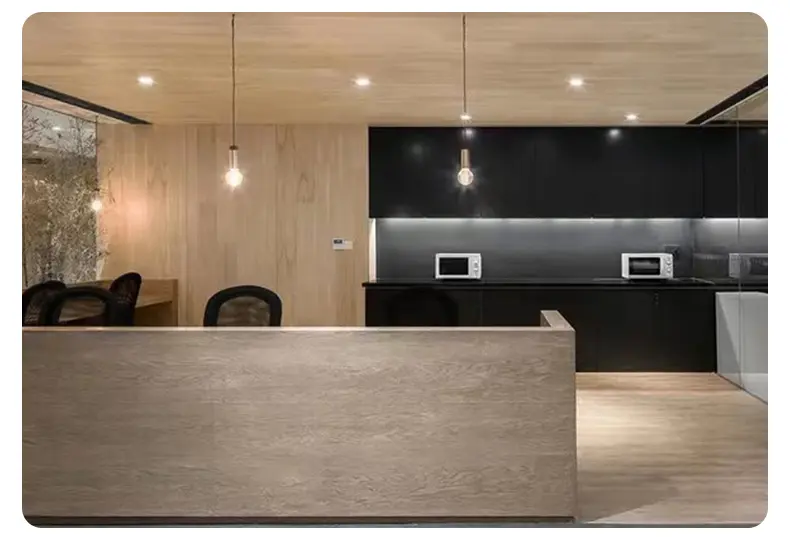

Living room: The perfect encounter between selected natural wood grain veneer and soft fabric, the warm wood texture is matched with geometric pattern carpet, and a warm and elegant social space is outlined in the interweaving of light and shadow. Italian designer Antonio Citterio once said: "Wood is the most vital design language."

Bedroom: The headboard background wall made of smoked oak veneer, its delicate texture and matte texture, combined with the hidden light strip design, creates a quiet atmosphere like a forest cabin. Research by the Polytechnic University of Milan shows that a wooden environment can improve sleep quality by 23%.

Study: The whole wall bookcase customized with North American black walnut veneer, combined with a suspended desk of the same material, builds a balance between rationality and warmth in the fragrance of books and ink. The director of the Vitra Design Museum in Germany pointed out: "A wooden office environment can significantly improve concentration."

Dining room: The combination of a Portuguese cork veneer dining table and an Italian Minotti dining chair weaves warm memories between food and conversation. Michelin chef Massimo Bottura particularly praised: "Wooden restaurants can make the dining experience more layered."

Core advantages: Why choose new wood veneer?

1. Extremely environmentally friendly, worry-free

⚡ Zero formaldehyde: Using food-grade PET laminating technology, no glue bonding is required, E0 environmental protection.

⚡ Sustainable materials: The base material contains more than 60% calcium powder (calcium carbonate), which can be naturally degraded, and carbon emissions are 52% lower than pure PVC (according to LCA life cycle assessment).

⚡ Non-toxic and safe: Passed the EU REACH regulation test, heavy metals such as lead and cadmium were not detected, suitable for sensitive scenes such as children's rooms/hospitals.

2. Super durable, worry-free and labor-saving

⚡ Waterproof and moisture-proof:

The waterproof effect is good, and it will not deform when exposed to water;

The lifespan in humid areas (such as coastal areas/basements) is 10-15 years, far exceeding the 5-8 years of solid wood.

⚡ Scratch and wear-resistant:

It will not leave scratches with sharp objects such as keys, and it is scratch-resistant and wear-resistant.

⚡ Hidden value:

Save 50% of construction time (easy installation)

Reduced maintenance costs by 70% (supports partial replacement)

3. Free design, perfect appearance

⚡ Texture revolution:

Can accurately reproduce 200+ rare wood grains (such as black walnut/rosewood/white oak);

Hundreds of color patterns can be customized, including mirror, water ripple and metal effects.

- Conclusion

It is not important whether the board wood veneer wall panel is "real wood". The key is that it satisfies people's pursuit of natural aesthetics in a more environmentally friendly and economical way. The new PVC + calcium-based wood veneer is becoming the mainstream choice of decorative materials due to its performance and plasticity. For consumers, it is necessary to recognize the needs (such as whether fireproofing and scratch resistance are required), compare film materials (PVC/PET), and choose a reliable brand (check the quality inspection report) to maximize its value.

- Free Samples

As more and more people choose this product, import and export companies have also increased their promotion efforts. In order to let people who are cooperating for the first time and trying to sell this product for the first time feel its value, we launched a free sample activity. If you need it, please feel free to contact us, and we will have a professional service team to contact you.